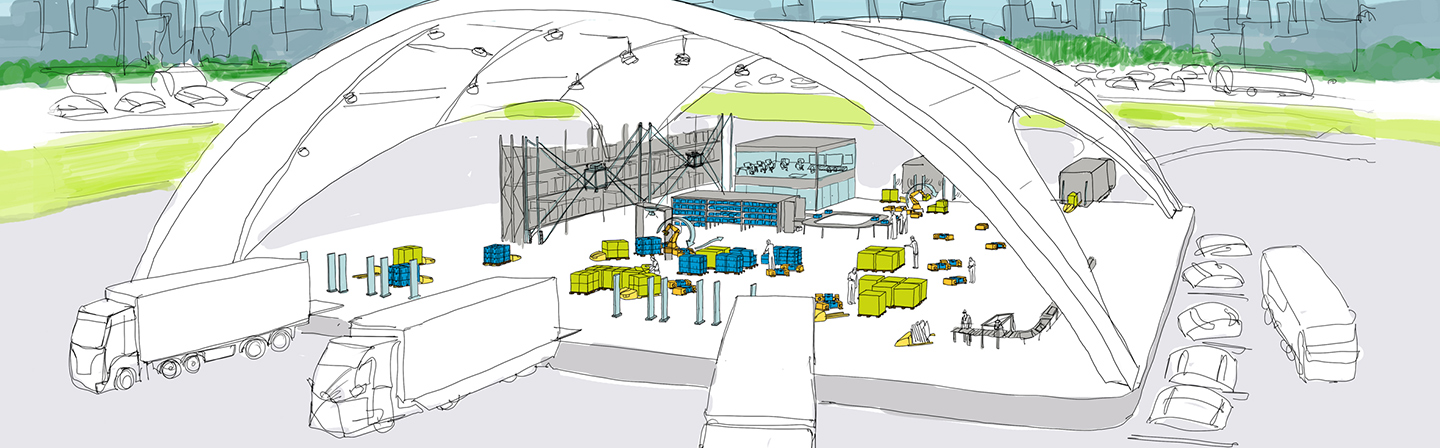

Finding a new production site in a relatively short period of time and moving to a new location along with the whole material flow system? What used to seem almost impossible has become a reality courtesy of Hub2Move, a cooperative research project, which supports the creation of an efficient, effective and configurable material flow system, which lives up to the remit of a moveable warehouse and provides the adaptability that is required of logistics today.

From vision to reality

As part of this vision, “hub” stands for a wide range of distribution warehouses, transshipment nodes and their material flow systems for physical product distribution. “Move” refers to the future adaptability of those hubs in terms of their geographic location and inherent function.

Advantages

Hub2Move does not only provide the advantages of an automated material flow system – such as cost-cutting, safe functional compliance and a high level of process transparency, but above all it provides the benefits of being adaptable to a wide range of locations. Users and suppliers both benefit from Hub2Move, users from being independent of their location, from its reliable operation and, as a result, from reduced costs and improved logistical supply chains. Suppliers benefit from expanded markets through more attractive material flow technology featuring cellular transport systems and autonomous vehicles.

Hub2Move and sustainability

Logistics, protecting resources and the environment – how can these work hand in hand? Hub2Move uses cutting-edge technologies which focus, among other things, on protecting resources and the environment. Energy-intensive goods transportation can now be a thing of the past thanks to the option of being able to move more easily to premises in areas where there is high demand, which in turn supports the sustainability of resources and the environment.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML