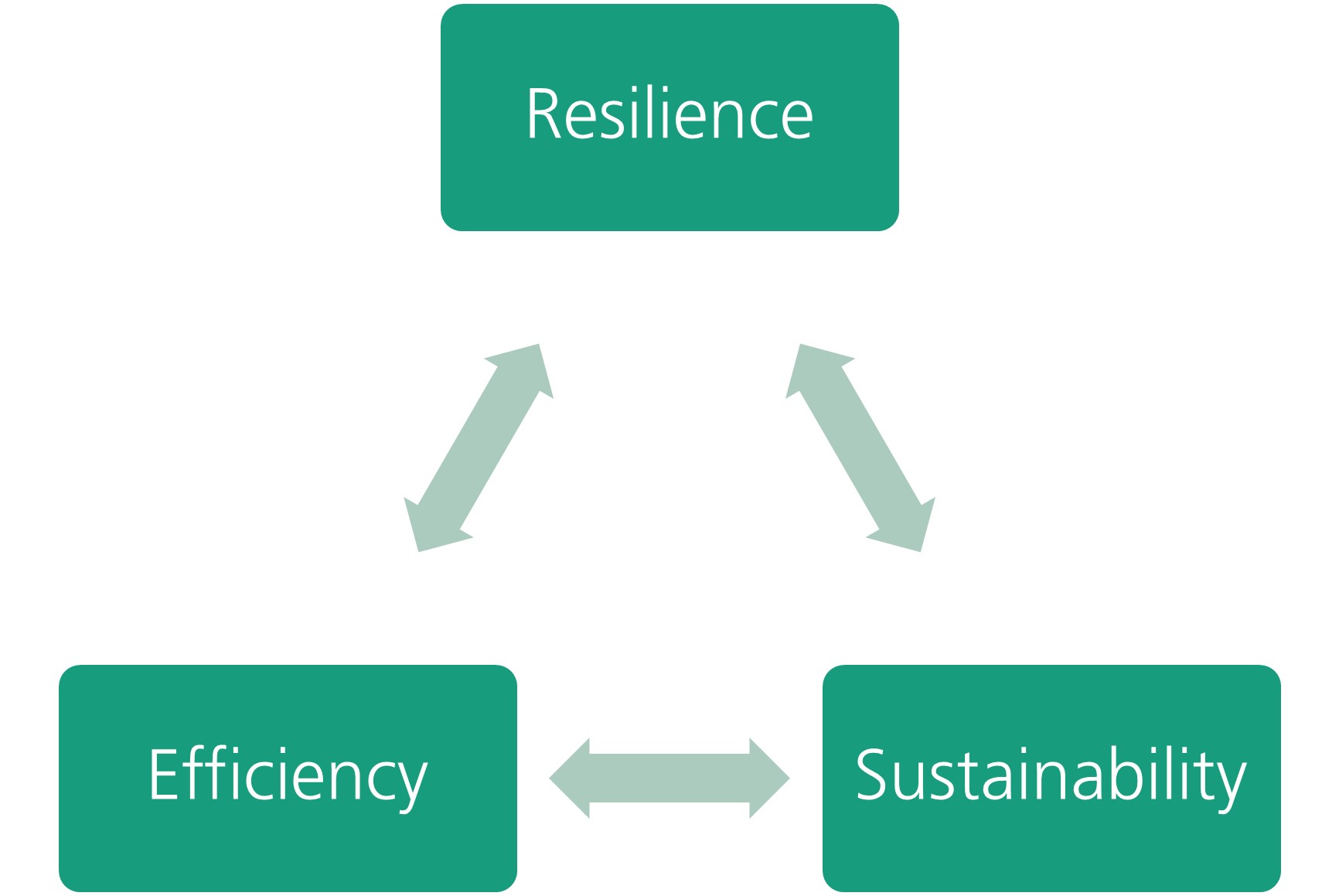

Our Goal: Supply chains in balance between efficiency, resilience and sustainability

The requirements for the design, configuration and operation of supply chains are constantly growing. In addition to a cost-effective and customer-oriented design of value networks, the aspects of resilience and sustainability are increasingly coming into focus. Particularly considering recent events such as the energy crisis, the Corona pandemic, or the Ukraine conflict in combination with a decreasing availability of fossil fuels, global warming, and a generally increasing frequency of global crises, the strategic work of the Supply Chain Engineering department is primarily designed to provide its customers with innovative solutions to these challenges.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML