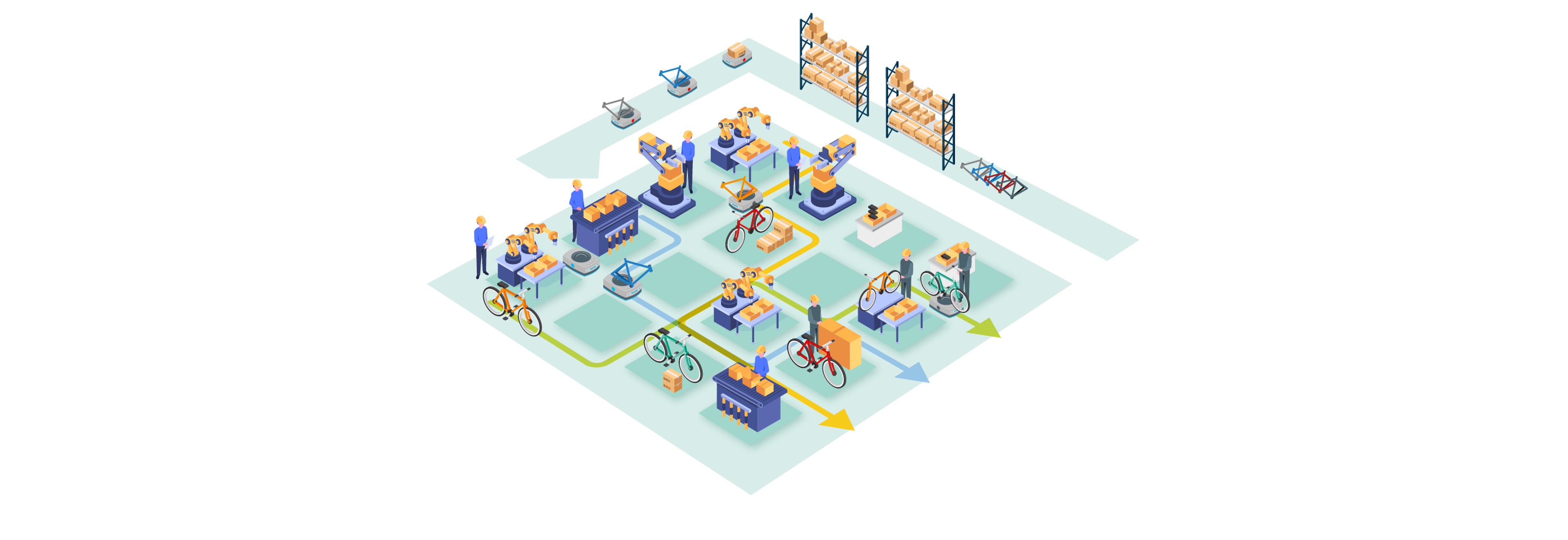

Matrix Production – Versatile Production

In comparison to traditional production systems, the matrix production system stands out due to high versatility, flexibility and resilience. Core elements of the matrix production are freely concatenated manufacturing and assembly stations with multiple process abilities, an intelligent production planning and control system for rapid and dynamic machine scheduling and a flexible transport system. Requirements are the integrated connectivity and the intelligence of the objects part of the value creation process. The free concatenation allows the avoidance of cycle time dispersion and leads to an increase in productivity. A rapid routing flexibility is archived through the redundance of manufacturing and assembly stations and an intelligent material flow control so that disruptions and shortages can be countered with rapid reactions. Instead of a fixed job schedule, the jobs are being approved at short term.

The matrix production combines the economic advantages of a traditional flow production system with the flexibility of a job-shop production. Therefore, the matrix production is suitable for fluctuating demand and high numbers of variants while being robust when disturbances occur. On the other hand, the increased degrees of freedom lead to an increase in complexity of the overall system.

Maturity level analysis for the transformation of production

To check, whether the matrix production as a concept for manufacturing is suited for your production, a wide analysis is needed. For the transformation of a traditional flow production to a matrix production, the Fraunhofer IML has developed a maturity level analysis which considers the entire transformation process holistically. The maturity level analysis actively supports the transformation of your production and can be used to define requirements for the replanning of a versatile production system.

We support the transformation process of your production and collectively develop strategies to implement a matrix production in your company.

Our approach to the conceptional design of your versatile production system

- Holistic analysis of the transformation process for the development of potential transformation paths

- Conceptual design of a rapid, dynamic and efficient supply of production

- Simulation and evaluation of the logistic performance

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML