Consistent orientation of production processes and use of resources towards the customer

In today's dynamic environment manufacturing companies can only ensure their competitiveness in the long term with a consistent orientation of the production processes and the availability of resources at the needs of the market.

With the objective of producing ideally only on demand, short lead times and low stocks with high efficiency at the same time are in the focus of consideration. The development of an efficient process management and concepts for a flexible resource management is the key success factor and advantage towards the competitors.

Your benefit

Because of the methodological competence of process management development and resource management in manufacturing, the Fraunhofer IML is the ideal partner to solve the following challenges:

- Reorganization of the structure and workflow organization in production to reduce costs, lead times and stocks

- Increasing service levels and customer orientation

- Implementation of process orientated production planning and control

- Development of concepts for economical and flexible use of resources

Furthermore we can offer you the following consulting focuses in this context:

- Concept and implementation of flexibility management to improve the orientation of your production during fluctuating workloads

- Development and implementation of disruption management, which increases the stability of your production processes by a fast identification of the disruption and a defined reaction.

- Development and implementation of solutions for workflow management to reduce process times of rerunning tasks and to minimize error processes and blind processes

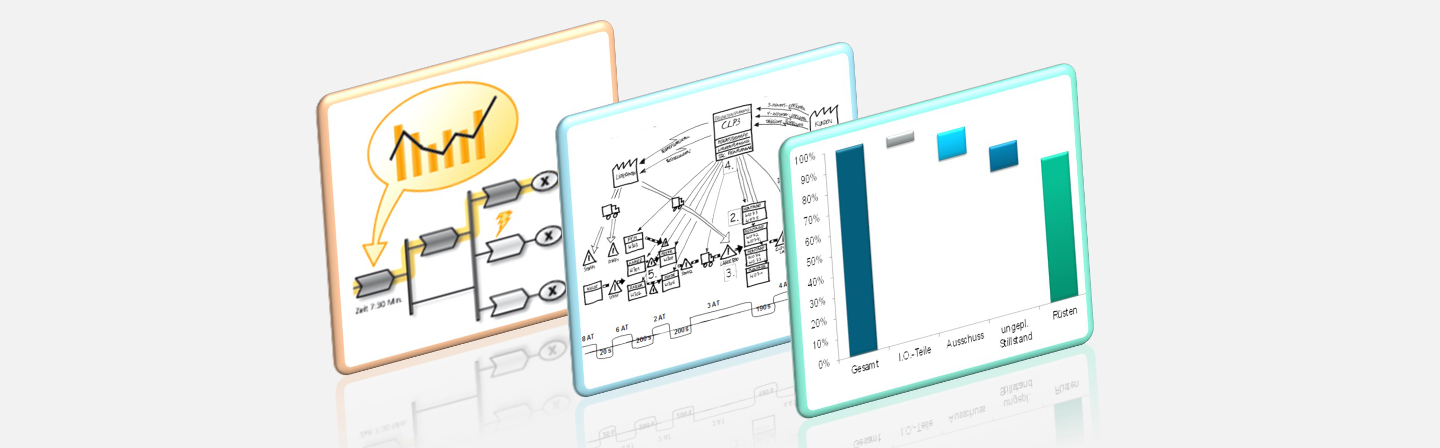

Our approach to process management

The Fraunhofer IML developed the method of process chain management to analyze, modulate and optimize process management in production. This supports you in visualizing and the analyzing your production processes from provision of parts to completion.

If you want to use the ideas of lean production, we can realize a lean production system for your company together with your employees by using value stream mapping and value stream optimization. The holistic approach is secured by supplementing, functional work structure analysis. Finally all works should be addressed correctly and unnecessary processes should be avoided.

The focus of resource management is on analyses that resolve the apparent contradiction of a high degree of utilization by a simultaneous high level of resource availability.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML