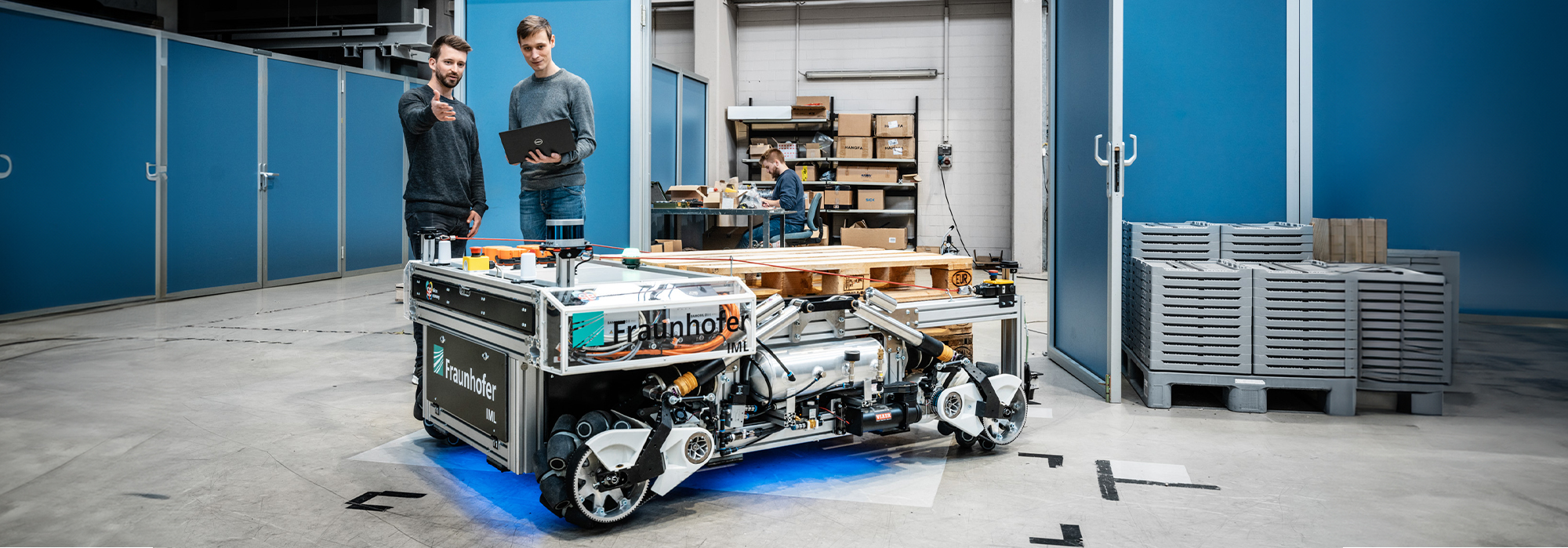

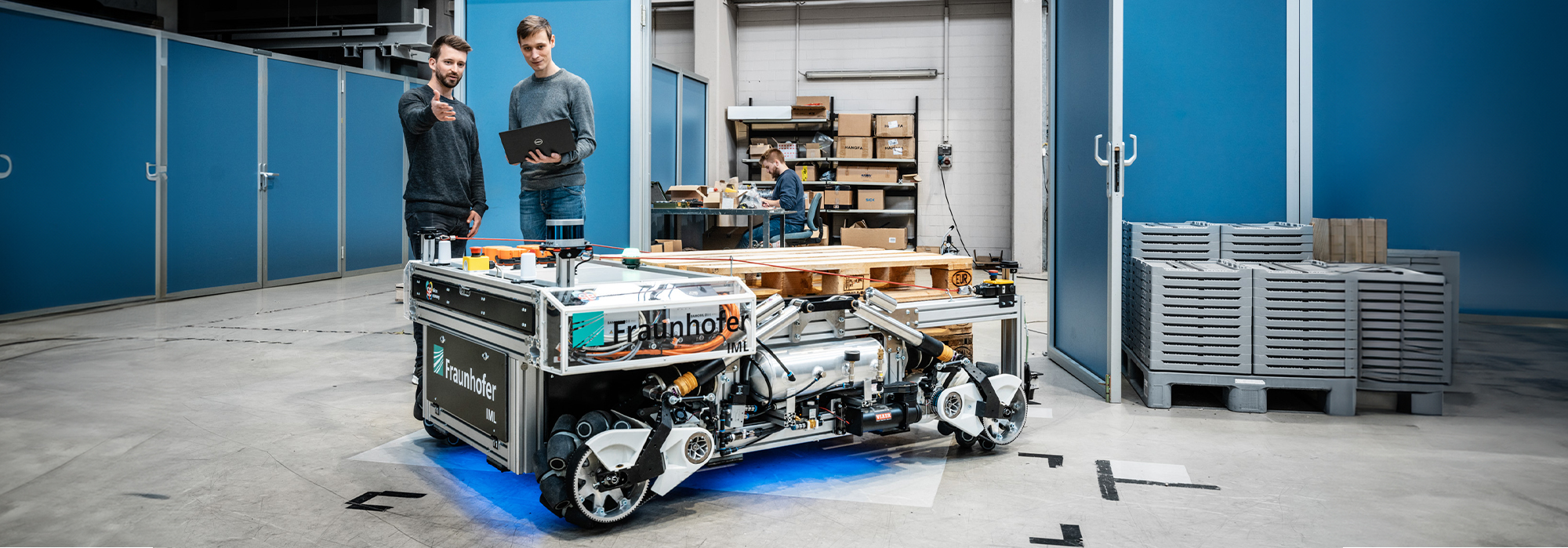

Prototype construction: advanced technologies for logistics solutions

Prototyping and technology development for logistics

From mechanics to electronics to control engineering: the existing expertise of the Fraunhofer IML in the sections of electrical engineering, microelectronics, additive manufacturing and mechanical manufacturing is bundled in the prototype center. The work of the interdisciplinary team ranges from the planning of mechanics and electronics to the subsequent production. The areas of expertise of the prototyping center include both the linking of different technical disciplines (including mechanical engineering, electrical engineering, computer science, robotics) and the use and combination of different manufacturing technologies (laser sintering, water cutting, etc.).

Since its foundation in 1981, prototyping has been one of the core areas of expertise of Fraunhofer IML. Components and prototypes can be manufactured and tested as needed in several modern, well-equipped laboratories. Close collaboration with other specialist departments makes it possible to draw on expertise from other sections as needed, for example to develop software components or specialized circuit boards. Printed circuit boards can be manufactured and assembled in the Microelectronics Lab. SMD components from size 0402 (1.0x0.5x0.45mm) are used here, which are also used in industrial circuits. The circuits can then be used in various IoT devices for logistics. It is also possible to manufacture individual components: thanks to the various 3D printers, even complex prototypes and pre-series can be printed.

Our services

In the workshops of the prototype center, prototypes and technologies are developed for both research and industrial projects. Whether automated guided vehicles, mobile robots, IoT devices, wearables or individual robotics solutions, the prototype center directly implements ideas for logistics applications.

The prototype center offers

- Development and construction of prototypes

- Manufacturing of mechanical components and prototypes: milling, turning, water jet cutting, edging

- Creating electronic circuits and cabling

Thanks to our versatile production capacities, ideas can be quickly implemented, with minor adjustments being made and tested directly. This shortens development cycles and minimizes implementation times. Continuous investment enables the development of cutting-edge technical solutions and also makes it possible to produce pilot series in preparation for industrialization.

Prototyping for applied logistics research

The prototyping center is geared towards...

- Companies that need support in implementing their prototypes

- Companies that do not have the in-house capacity to design or manufacture components and are looking for a competent partner to help them realize their idea

- Logistics service providers seeking to optimize warehousing and order picking processes

- Manufacturers of logistics equipment for the prototyping of new machines and technologies

- Companies interested in new warehousing technologies or automation solutions

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML