Datenfabrik.NRW

Research project focusing on the development of intelligent solutions taking into account the latest technologies for manufacturing companies

Digital transformation of production environments - a guiding principle with lighthouse character

The overall objective of the Datenfabrik.NRW research project is to shape the digital transformation of real production environments and their further development into data-driven future factories. These future factories are to serve as a blueprint for manufacturing companies in NRW and beyond. The design of the digital transformation is carried out by means of tapping the application potentials of state-of-the-art technologies such as artificial intelligence in production environments and bundling the tools to create highly flexible, efficient and high-quality manufacturing environments. Progress in data analytics and artificial intelligence holds immense potential for the realignment of production environments at this point, which is to be developed holistically within the framework of the Datenfabrik.NRW.

Future challenges of the digital transformation

The great challenge of the factories of tomorrow is to design the digital transformation on the one hand as a comprehensive restructuring and on the other hand as a successive integration process into existing structures. Central to the success of the digital transformation of production environments is a holistic data strategy, an essential component of which is coordinated and efficient data collection, storage, and use, considering the highest security requirements. This enables the further utilization of data in superordinate and subordinate corporate areas to establish decision support in a complex environment.

Development and implementation of user potentials of AI for production

In shaping the successful transformation to a data-driven factory of the future with self-optimizing value creation processes, three fields of action emerge. First, intelligent solutions for industrial production must be developed. Second, a method and technology transfer are required that enables continuous integration of the solutions into existing processes and enterprise architectures. Thirdly, holistic change management must support companies in their transformation. To fully address the fields of action described, a new form of application-oriented research is required.

In the interdisciplinary interaction of research and industry partners, methods for the systematic design of AI applications in the production of tomorrow are to be developed as part of the Datenfabrik.NRW research project. The focus of the systematics to be developed is on the collection, storage, and use of data from engineering, production and logistics.

Broad transfer based on lighthouse factories

In the project, concrete and transferable use cases are developed that demonstrate the potential benefits of the latest technologies in production. The use cases are jointly designed, piloted and transferred. The findings will be made available to interested companies as best practices via established industry networks, and access to individual solutions and insight into the effective structures of the best practices will be made possible. Various information and demonstration formats will be established to communicate the results. An overarching smart factory data platform that provides a real industry database will be used to develop innovative solutions.

Transformation Area

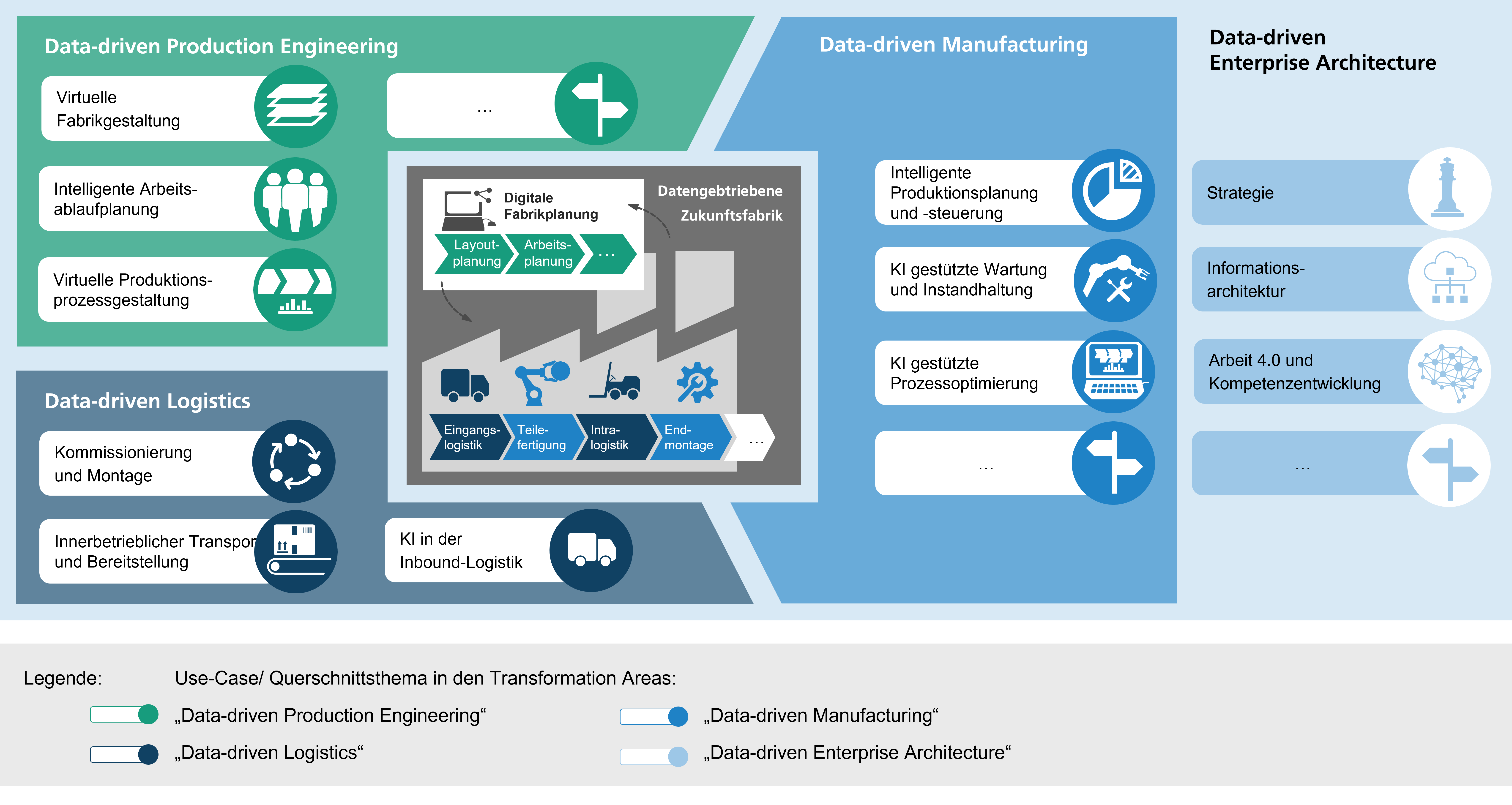

The four transformation areas Data-driven Production Engineering, Data-driven Manufacturing, Data-driven Logistics and Data-driven Enterprise Architecture form the starting points for concrete use cases and cross-cutting themes of the lighthouse factories. All areas are closely interlinked and form the cornerstones of the lighthouse factories through the integration of state-of-the-art technologies and methods.

The role of Fraunhofer IML:

In support of Datenfabrik.NRW, our main task is to coordinate the Transformation Area Data-driven Logistics and the design of AI in inbound logistics and the supply chain. In particular, current methods from the field of artificial intelligence as well as our many years of experience in the use of dynamic simulation for the development of intelligent systems are brought to bear. Specifically, we are concerned with the identification of influencing factors on the supply chain and inbound logistics. The identification of these influencing factors is an essential component in the development of AI-based models. Scenario-based decision support using dynamic simulation manages the balancing act from the developed models to reality and thus makes the key contribution to managing complex and uncertain events in the context of the complexity of today's supply chains.

Partner:

- CLAAS Selbstfahrende Erntemaschinen GmbH

- Schmitz Cargobull AG

- Duvenbeck Kraftverkehr GmbH & Co. Spedition

- NTT DATA Business Solutions AG

- MotionsMiners GmbH

- Fraunhofer IAIS

- Fraunhofer IEM

- Fraunhofer IML

- Fraunhofer IOSB-INA

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML