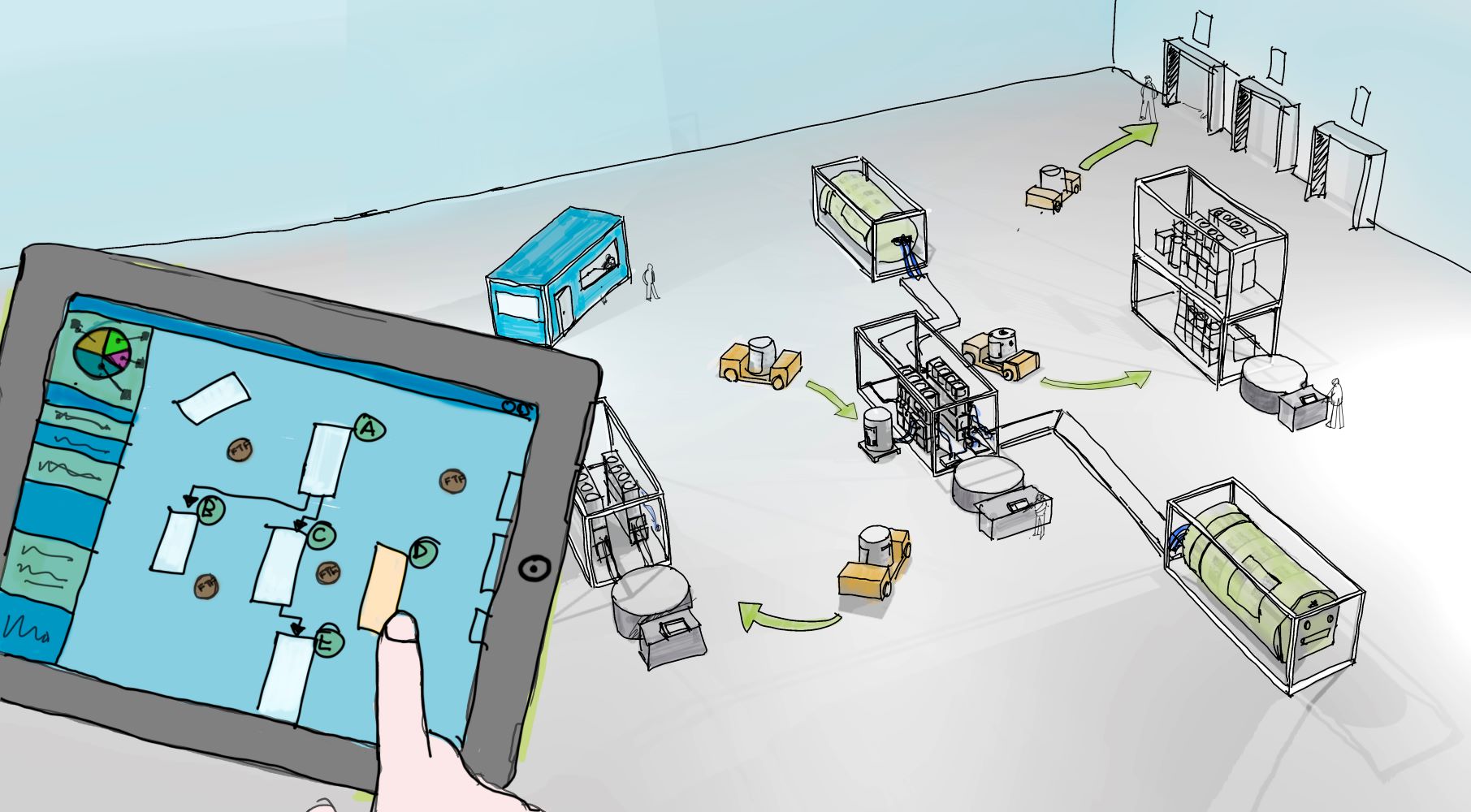

Many branches of the process industry such as the pharmaceutical and the fine chemicals industry are confronted with a growing uncertainty and dynamic market behaviors, increased requirements for product differentiation and shorter product life cycles. Challenges arise from long periods for planning and realization, rigid production lines and inflexible production layouts. In this context the importance of a modular and flexible overall concept increases. Modular concepts for production and logistics constitute a paradigm shift in the process industry. Modular concepts have been successfully developed in the field of production so that the field of logistics is set to follow up. However, there are no standardized and modular concepts that meet the flexibility requirements of volatile markets. Through the use of these concepts the existing rigid planning strategies shall be abandoned and a flexible and adaptable environment is created. Modular logistic concepts are quite innovative in the sense that they enable a short-term reaction to changing market conditions through up- and down-scaling of the required capacities to provide these capacities efficiently and according to the demand.

The project MoProLog (»Modular Production Logistics«) has been initiated to reach the goal of a modular and standardized production logistics. Together with the consortium partners BASF SE, BEUMER Maschinenfabrik GmbH & Co. KG, Alfred Talke GmbH & Co. KG, Fachhochschule Südwestfalen and Helmut-Schmidt-Universität Hamburg, energy efficient and modular concepts for logistics systems along with their interfaces are being designed. As an example, a modular palletizer is being developed to demonstrate the project results. The project MoProLog is part of the ENPRO project initiative and is conducted and promoted by the Federal Ministry for Economic Affairs and Climate Action within the funding initiative »Energieeffizienz in der Industrie«.

For more information on the ENPRO initiative click here.

Project duration

01.11.2019 – 31.10.2022

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML