Energy efficient supply chain design

May 22, 2023

Not only climate change, but also the current worldwide crises and conflicts underline the necessity of concepts and solutions for the economical and efficient use of energy. Logistics has been a driver of innovations and models in the field of sustainability for many years. Currently, Lucas Schreiber, scientific employee at Fraunhofer IML, is working on a “Planning concept for an energy-efficient supply chain design” for his dissertation. This could solve many problems for industry.

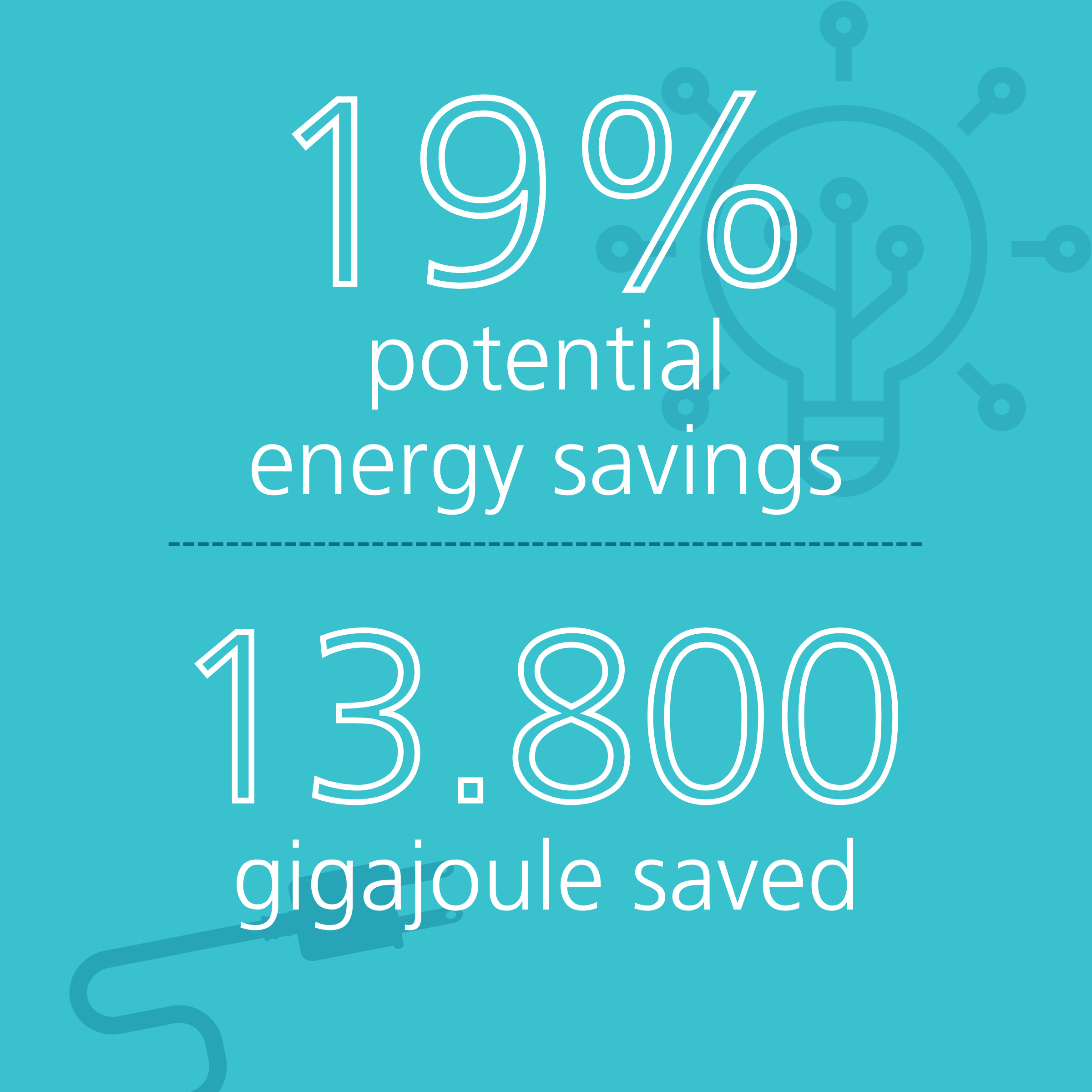

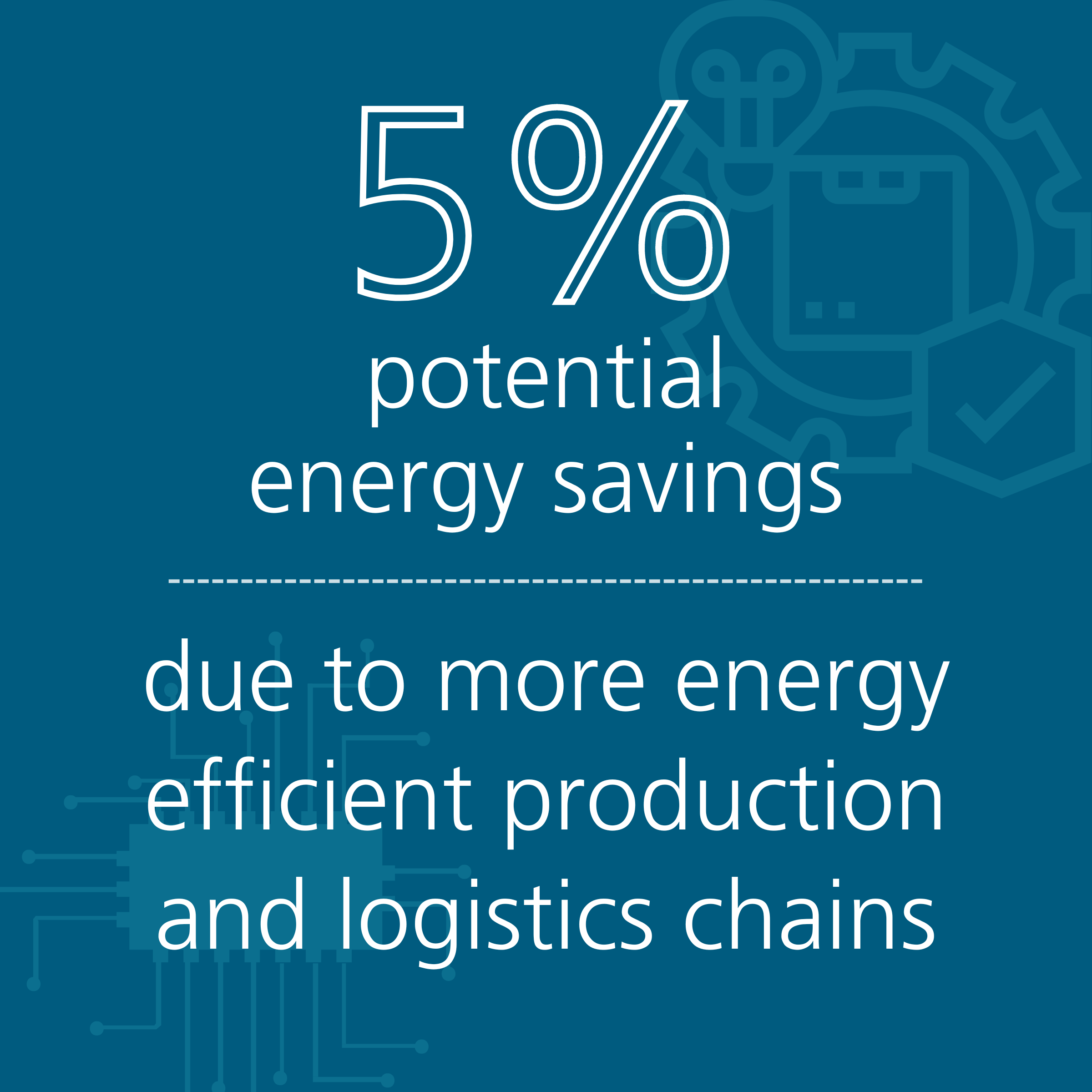

Energy demand has been rising for years, while the availability of fossil fuels has been declining. A situation that is becoming increasingly critical, especially in view of the current energy crisis. Making use of potentials for saving energy in supply chains is therefore becoming an important aspect for companies. From the point of view of corporate logistics, this is a rather strategic task. The concept that Lucas Schreiber wants to develop in his dissertation is intended to offer companies assistance that is as simple as it is effective.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML