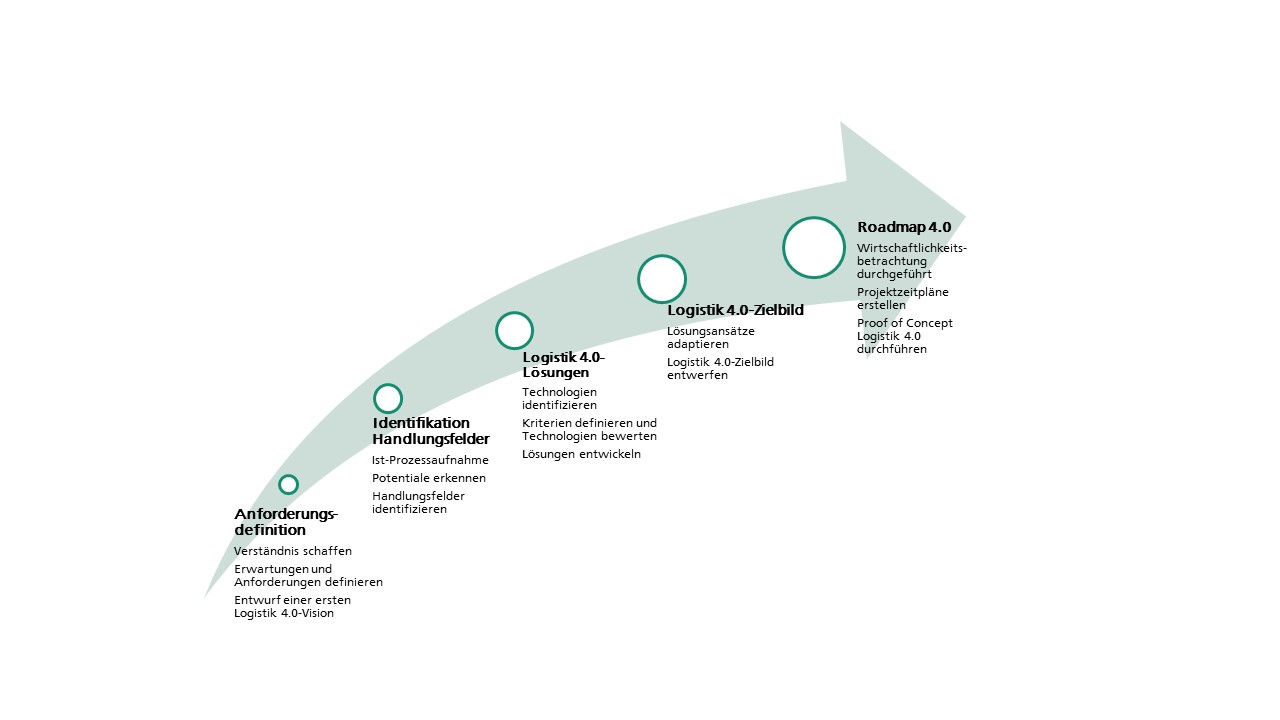

1. Definition of requirements

Individually in joint workshops with the customer, a uniform understanding of the topic of Logistics 4.0 is created at the start of the consulting process, information is provided about the breadth and depth of the topic Logistics 4.0, and its opportunities and possibilities (innovation, trends, challenges, potential benefits etc.), as well as possible applications in logistics are identified. Furthermore, expectations and requirements are meticulously documented, framework conditions are defined, and an initial Logistics 4.0 is developed.

2. Identification of fields of action

In this consulting phase, as-is surveys and a detailed inspection are carried out at the selected location. In further joint workshops, potentials and fields of actions are derived, which offer starting points for future-oriented Logistics 4.0 technologies for your company. The Intralogistics and -IT Planning department supports this process with technical and methodological expertise.

3. Develop Logistics 4.0 solutions

The Intralogistics and -IT Planning department compiles a longlist of Logistics 4.0 technologies from external companies in the private sector and products from its own research, regardless of the identified optimization potential. Logistics 4.0 technologies are evaluated using the evaluation criteria from phase 1 and a shortlist is created. Furthermore, requirements for future technologies are defined as needed in order to find solutions. Logistics 4.0 solutions take into account both hardware and software products. The selection and transfer of Logistics 4.0 technologies to a shortlist serves as the foundation for the subsequent phase of developing a Logistics 4.0 vision.

4. Logistics 4.0 vision

In the consulting phase, a Logistics 4.0 target vision is developed under the motto “Think big, start small“ based on the selected Logistics 4.0 technologies and in close collaboration with the customer. The company-specific target picture is intended to show that the logistics system could look like using the adapted Logistics 4.0 technologies based on the vision created in phase 2 and the newly gained knowledge. The previously defined Logistics 4.0 solutions are aggregated into a holistic logistics system during the process. The emphasis is on optimizing the flow of materials and information for each use case.

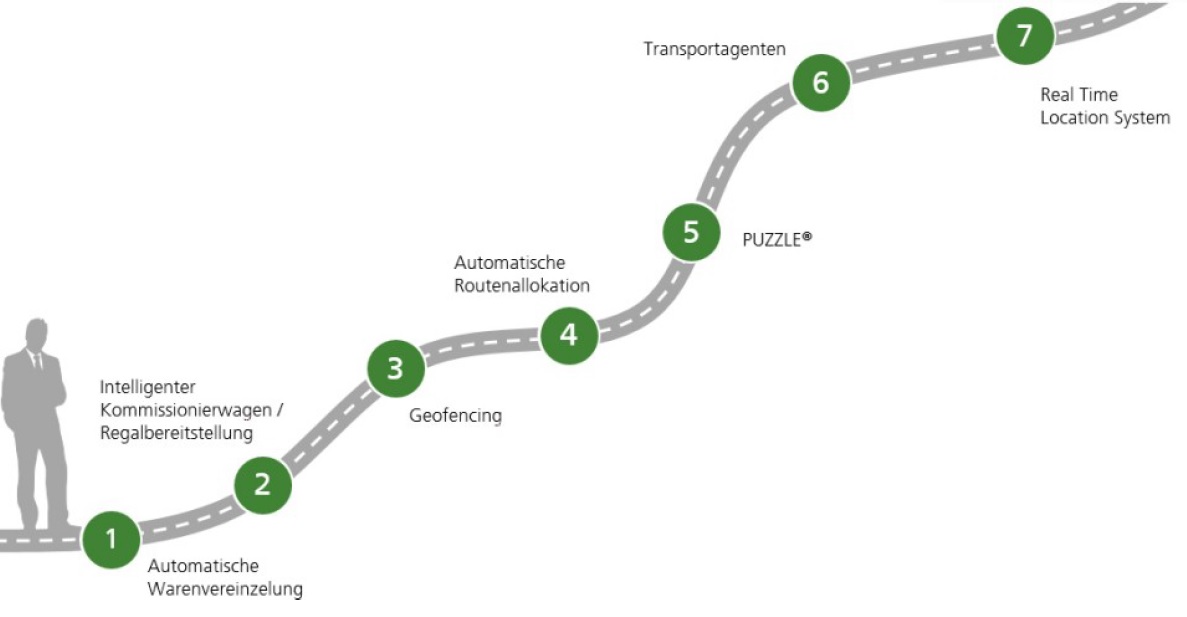

5. Roadmap 4.0

A roadmap is then created a part of project planning, a project schedule is created, and work packages are defined in order to prepare the warehouse for the future with a step-by-step migration of Logistics 4.0 applications and technologies. During the process, the technologies orchestrated in the holistic Logistics 4.0 version are placed in a logical implementation sequence while keeping the time horizon in mind.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML