L4MS-Initiative (Logistics for Manufacturing SMEs)

L4MS-Initiative (Logistics for Manufacturing SMEs)

Launched on October 1, 2017, the L4MS [1] project (Logistics for Manufacturing SMEs) is funded by the European Commission and coordinated by the VTT Technical Research Center in Finland. This project focuses on fully digitizing intralogistics automation in factories. The aim is for suppliers of automation and logistics solutions to be able to develop and be up to ten times faster and more cost-effective than at current prices.

Need for improvement

In a typical factory, 25% of the workforce, 55% of the factory floor, and 87% of the production time are attributable to the transport of parts and components. While large manufacturers are rapidly using mobile robots to increase productivity and flexibility in the factory, less than 2% of European SMEs (small and medium sized enterprises) use advanced manufacturing technologies. For SMEs, which represent 98% of manufacturers, there is a danger that European industry will be left behind.

That is where L4MS comes in, enabling cost-effective, flexible and agile logistics automation in small batches, achieved through robotics and other advanced technologies such as artificial intelligence and virtualization.

OPIL - A comprehensive platform for Intralogistics

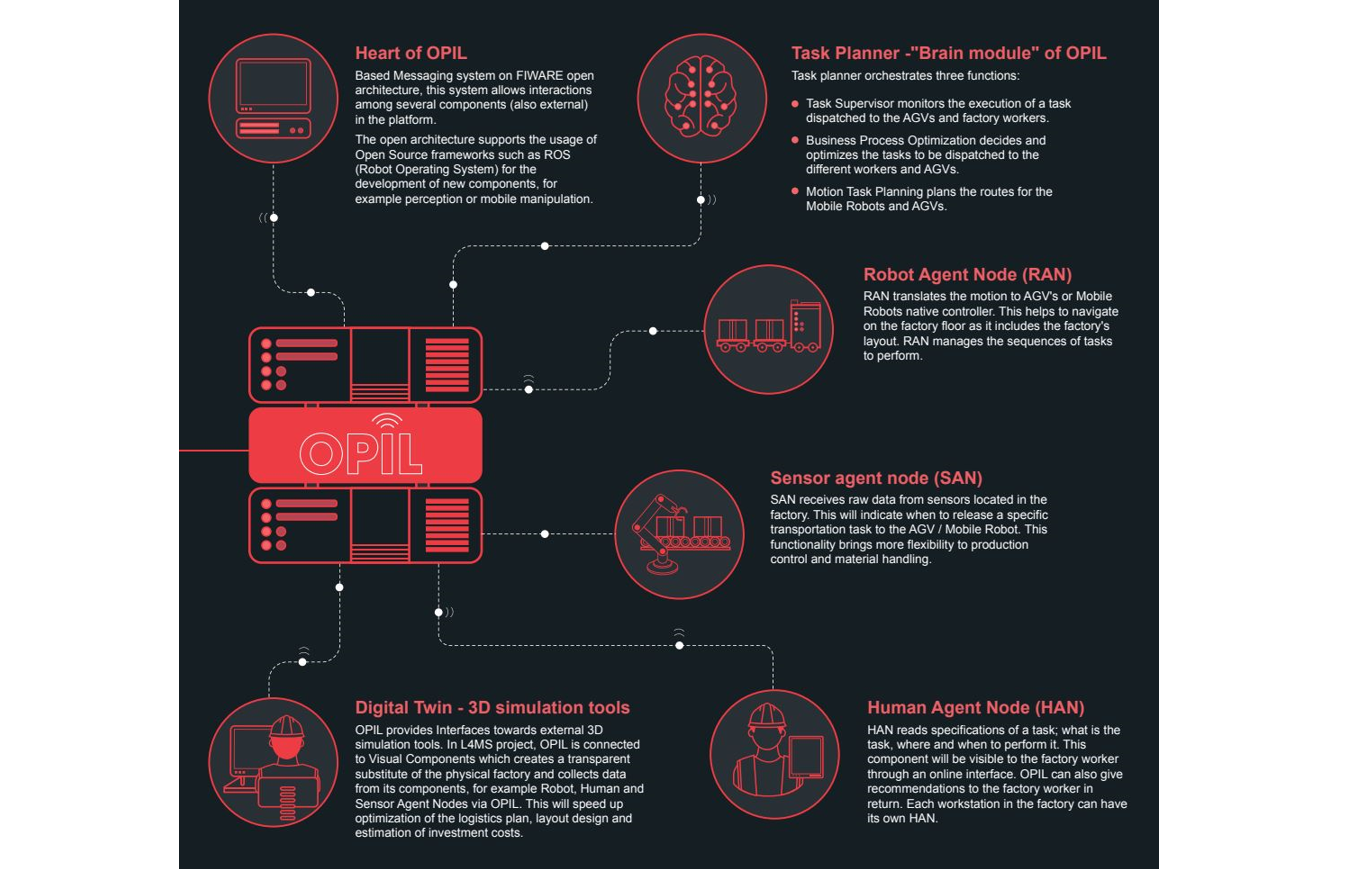

L4MS offers complete digitalization with OPIL (Open Platform for Innovation in Logistics [OPIL]) to enable cost-effective deployment of small and flexible logistics solutions. Other benefits include no infrastructure changes, no production downtime and no in-house know-how, making an investment in logistics automation for manufacturing SMEs extremely attractive.

Using OPIL and an external 3D simulation (with an example implementation of Visual Components®), highly autonomous, configurable and hybrid (human-robot) logistics solutions can be enabled.

With OPIL as the base technology for rapid experimentation and innovation on the market, existing and proven components can be easily updated, adapted or replaced with more advanced components as new technological inventions become available.

OPIL architecture [2]

The OPIL architecture consists of 3 layers: The top layer corresponds to the software system Layer; the middle layer comprises the cyber-physical middleware and the bottom layer the IoT agent nodes, consisting of humans, robots and sensors.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML