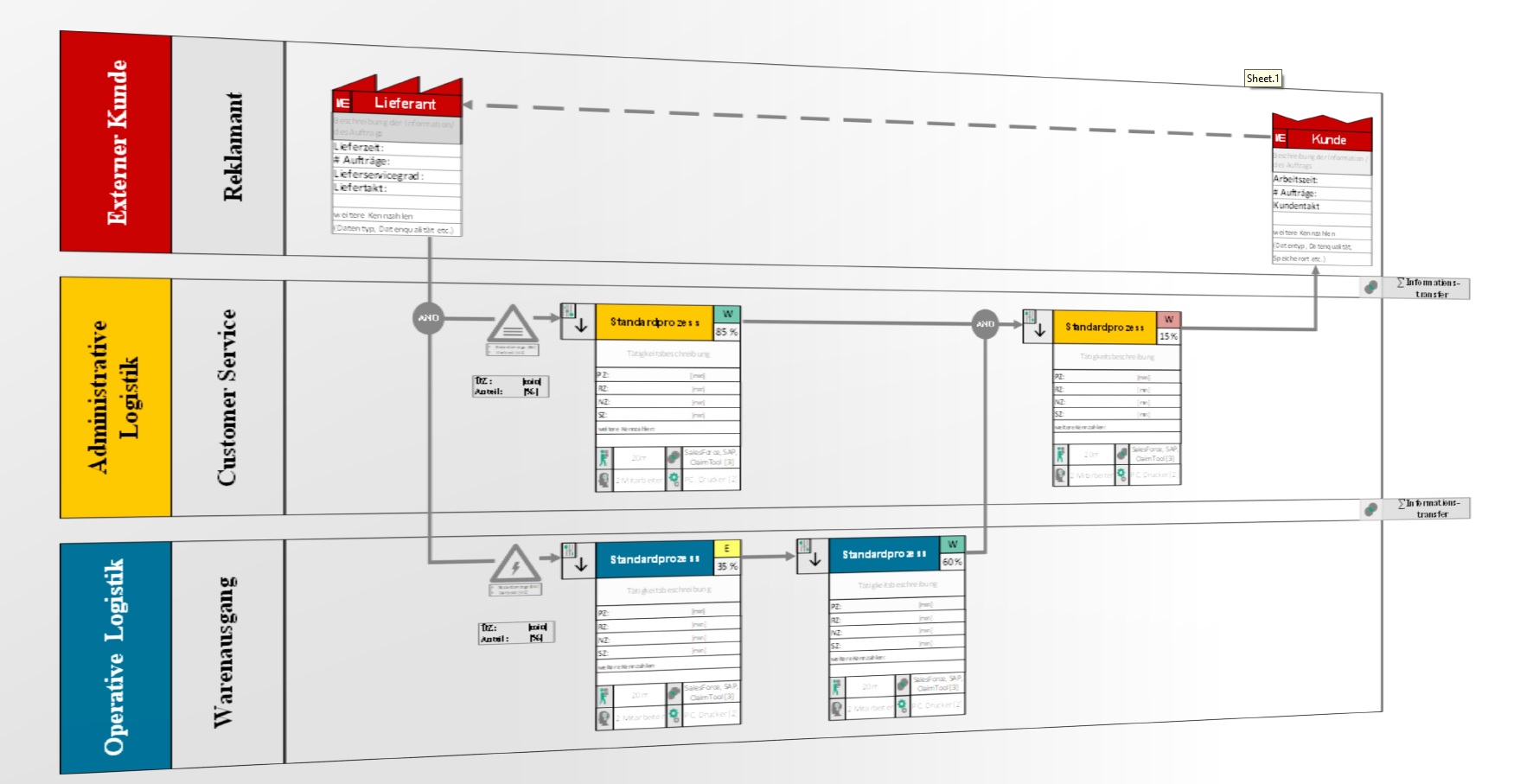

Value stream mapping in Logistics Administration

Administrative processes in intralogistics are distinguished by intangibility of information, multiple interfaces, and a lack of standardization. Employees in administration are typically involved in a wide range of tasks with varying degrees of difficulty and know-how requirements, which results in d which results in duplicate work, unclear process responsibilities, and excessive resource use.

Appropriate and practical methods are required to meet the diverse and complex demands placed on the analysis and optimization of administrative logistics processes. Value stream mapping has established itself as the most successful and effective method for this purpose in production and operational logistics.

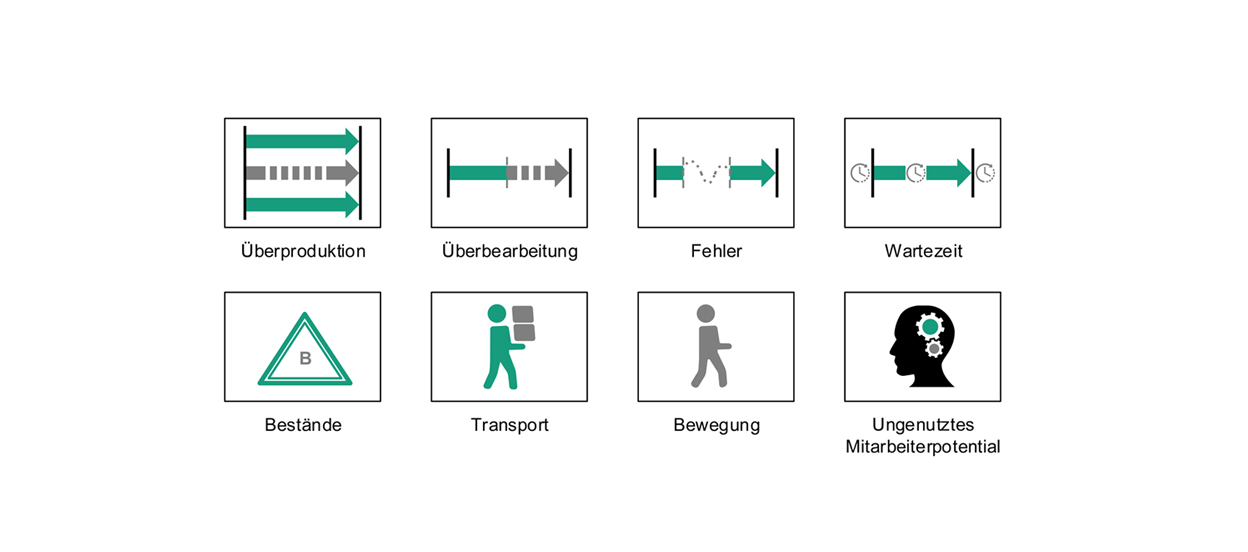

However, there has been a lack of methods for visualizing and quantifying value-added components in administrative logistics. Types of waste are one possibility for identifying these shares. These include unused employee potential, errors, and waiting times, which are the most significant efficiency killers. These must be eliminated on a continuous basis.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML