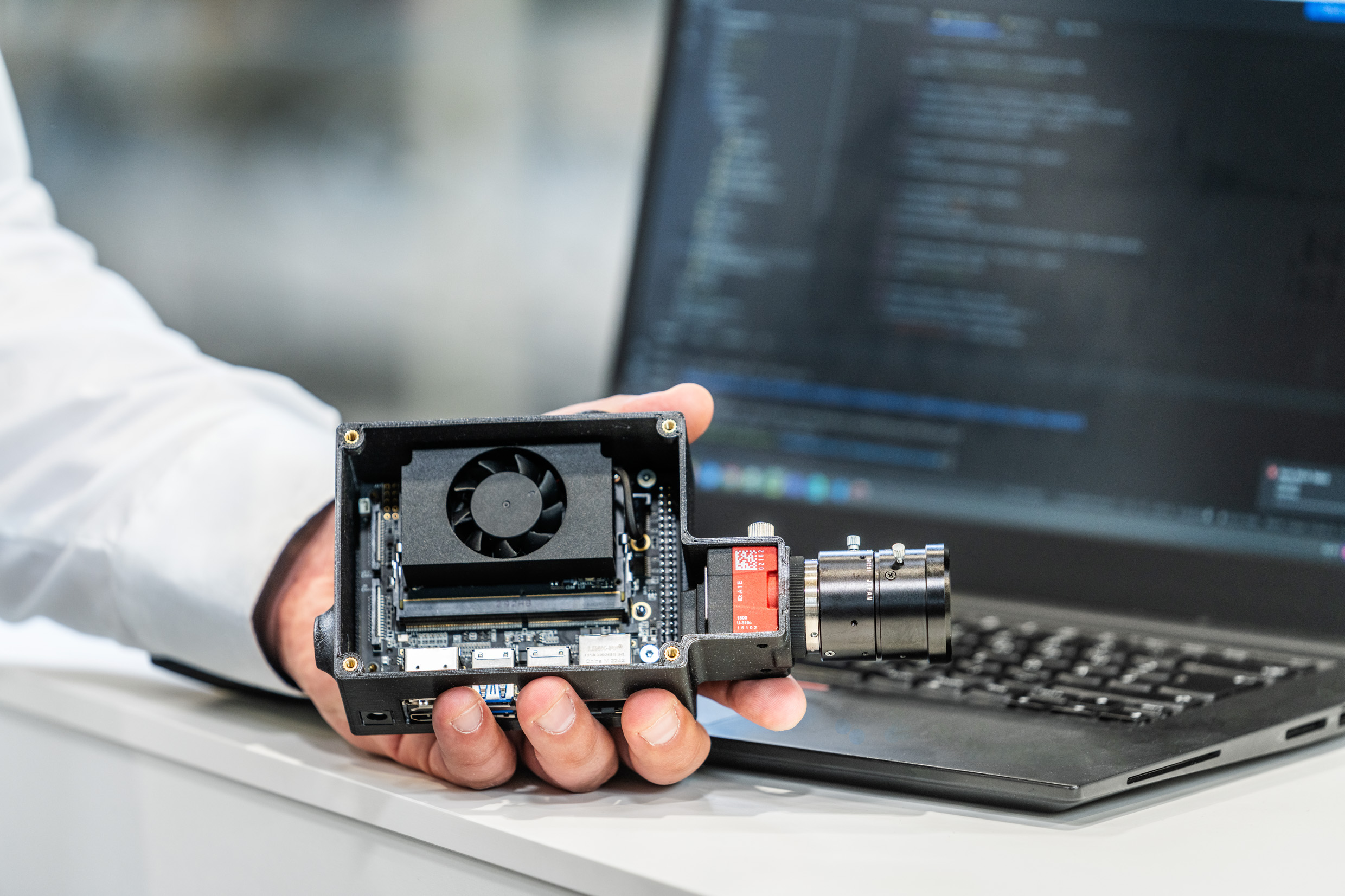

Computer vision (CV) is a branch of artificial intelligence and computer science that deals with the automatic processing and analysis of images and videos. The goal is to give AI models the ability to interpret and understand visual information similar to how the human eye does. AI-supported image processing enables companies to capture conditions and data in real time and use this data to optimize their processes. This data includes the current positions of load carriers (e.g., pallets), inventory levels, storage space fill levels, and the load status of trucks.

Optimization of everyday operations

Computer vision makes it possible to optimize processes without having to interrupt them. For example, ongoing processes in the warehouse can be recorded using cameras and analyzed for optimization potential without disturbing ongoing operations.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML