Due to the constantly growing amount of available data and computing power and the associated new possibilities of artificial intelligence (AI) to create transparency and identify optimization potential, the question arises as to what the AI-supported production of the future will look like. The Datenfabrik.NRW research project is pioneering work on this question and shaping a digital transformation in real production environments. The overall goal of the project is the successful implementation of a digital transformation of industrial companies into data-driven future factories with self-optimizing value creation processes.

The consortium partners of the project are Fraunhofer IEM, Fraunhofer IOSB-INA, Fraunhofer IAIS and Fraunhofer IML, the application partners CLAAS and Schmitz Cargobull, as well as Duvenbeck Kraftverkehr, NTT Data and MotionMiners. Together, the partners in the project are working on the following three fields of action:

- Development of concrete solutions for the use of artificial intelligence in industrial production.

- Creation of a method and technology transfer from science to companies, which enables a continuous integration of AI-supported solutions into the operational business.

- Designing holistic change management that ensures support for the companies during the transformation. The factories of the companies CLAAS and Schmitz Cargobull act as application environments in which the consortium implements AI solutions developed in areas such as factory planning, production and logistics.

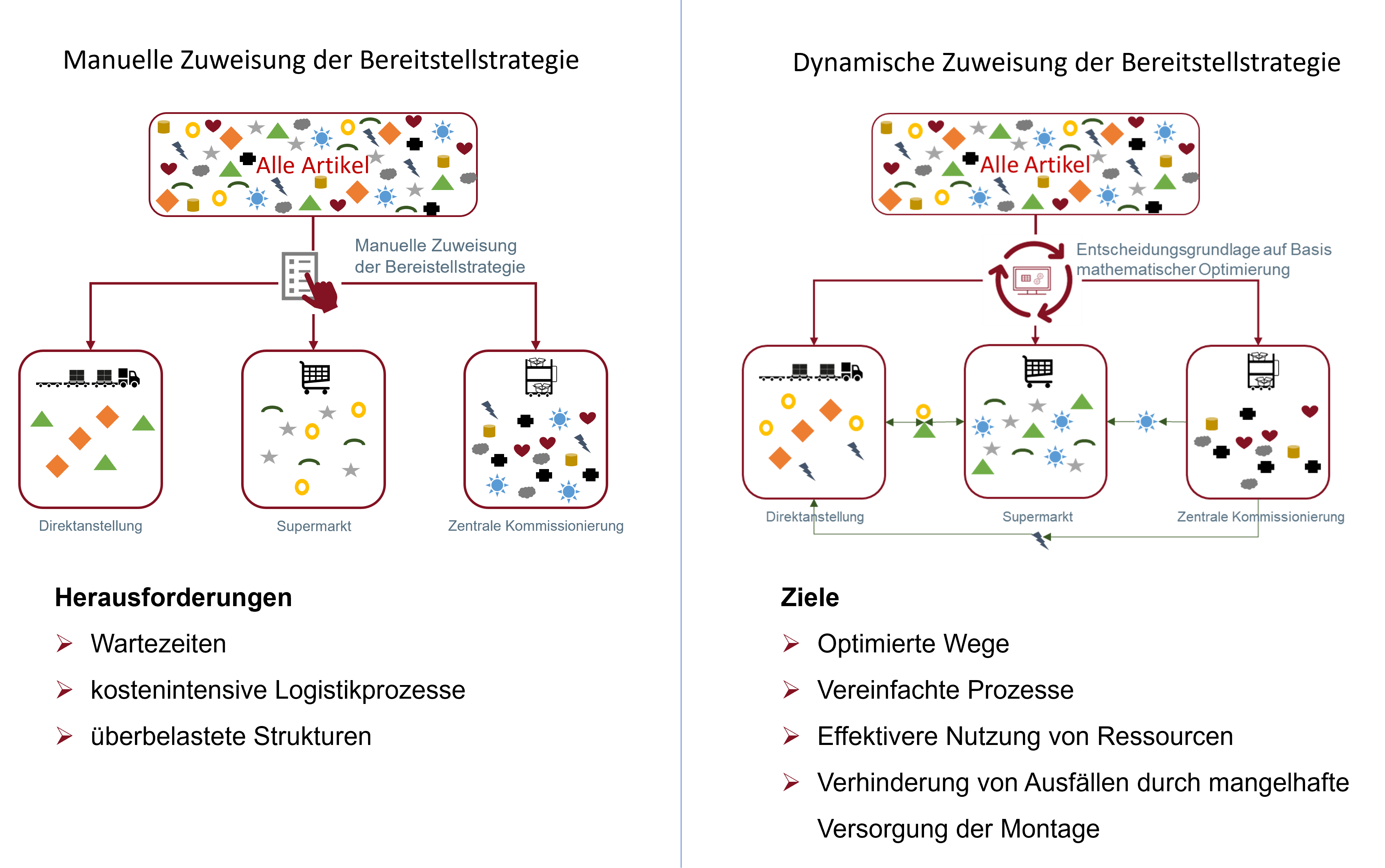

Together with the consortium partners, Fraunhofer IML is shaping and working on the transformation area “Data-Driven Logistics”, with the Intralogistics and IT Planning department focusing mainly on the optimization potential in the interaction between order picking and assembly. Data on warehouse movements and processes will be collected and analyzed, and processes, resource planning and order load in order picking will be optimized using AI-supported methods. In a first concrete use case, the provisioning strategy of the different materials at the application partners will be analyzed and optimized considering size, weight, capacity and performance constraints in the different functional areas.

Fraunhofer Institute for Material Flow and Logistics IML

Fraunhofer Institute for Material Flow and Logistics IML